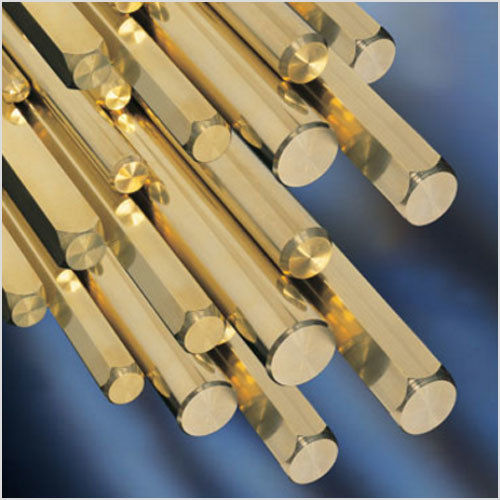

Naval Brass Rods

Product Details:

- Material Brass

- Grade HIgh

- Alloy Yes

- Temper 1/2 Hard

- Shape Round

- Click to View more

Naval Brass Rods Price And Quantity

- 400.00 - 1000.00 INR/Kilograms

- 500 Kilograms

Naval Brass Rods Product Specifications

- Round

- HIgh

- Brass

- Yes

- 1/2 Hard

Naval Brass Rods Trade Information

- 150 Kilograms Per Month

- 3 - 4 Week

Product Description

We are one of the eminent manufacturers, suppliers and exporters of Naval Brass Rods. These are manufactured by our experienced professionals using modern machinery and premium grade raw materials that are sourced from dependable dealers.

| Chemical Requirements | Grade I | Grade II |

| Copper | 61.0 - 64.0% | 59.0 - 62.0% |

| Lead | 0.20% max | 0.50 to 1.0% |

| Tin | 1.0 to 1.50% | 0.50 to 1.0% |

| Iron | 0.10% max | - |

| Other Imp. | 0.20% max | 0.20% max |

| Zinc | Remainder | Remainder |

| Physical Properties | |||||

| Condition | Size | T.S. Kg/mm2 | EL% Min | T.S. Kg/mm2 | EL% Min |

| Half-Hard (HB) | Upto 12.5 | 40 min | 18% | 40 min | 15% |

| Fabrication Properties | |||

| Capacity for being | |||

| Cold worked | Fair | Poor | |

| Hot Worked | Excellent | Good | |

| Machinability Rating | 30% | 50% | |

| Forgeability Rating | 90% | 90% | |

| Silver Alloy Brazing | Excellent | Good | |

| Soft Soldering | Excellent | Excellent | |

| Oxyacetylene Welding | Good | Not Suitable | |

| Uses |

| Gr I : Condenser Components, Propeller Shaft, Marine hardware where bending is required. |

| Gr II : Marine Hardware, Screw Machine, Valve Stems and Components for Naval use. |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Brass Rods & Profiles' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese